MATIS®

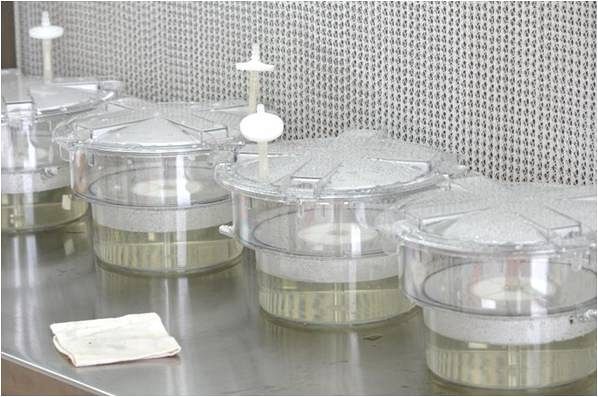

Large temporary immersion bioreactor

Easy to use, effective and resistant over time, it represents the ideal solution to achieve large-scale production quality.

Developed under industrial conditions in collaboration with  Montpellier in France

Montpellier in France

Result of 12 years of research

The MATIS® is the result of 12 years of research on micropropagation in temporary immersion systems conducted by the CIRAD team (France), under the leadership of Drs. Hervé ETIENNE and Frédéric GEORGET. The MATIS® serves both the requirements of industrial production and laboratory research.

MATIS® benefits

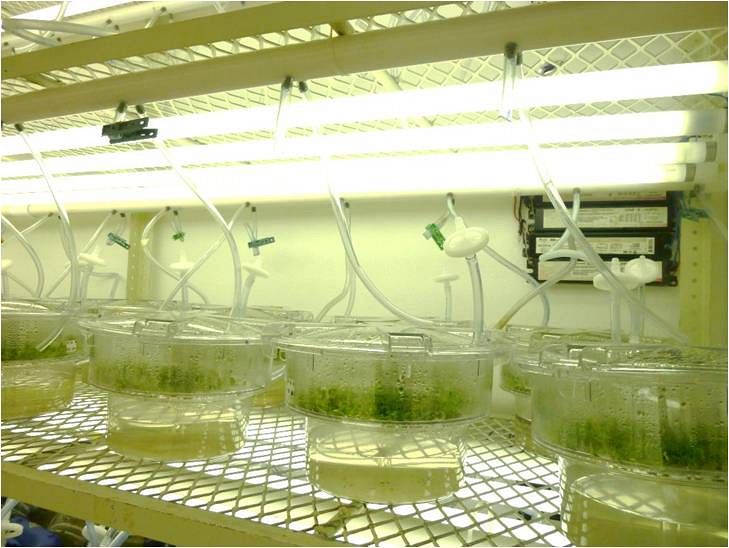

- High transparency for optimal light scattering

- Horizontal design favoring a homogeneous development through better spreading of the plants and excellent light transmission

- Monobloc device for an excellent impact resistance, an easy handling, and a large culture volume

- Easy access and manipulation to the plant material produced, through a large opening on top of the bioreactor and an innovative locking system with quick clamping

- Tested on many species in micro-propagation

- Result of 25 years experience in bioreactors from a group leader in the temporary immersion technology, including 10 years at industrial level

- Tested under industrial conditions in Mexico, Nicaragua and Costa Rica

During two years of testing under industrial conditions, the bioreactor MATIS® worked effectively on many plant species (coffee, banana, agave, prunus …).

Exceptional biological performance

The unique design of the MATIS offers an exceptional biological performance in comparison with most bioreactors currently on the market, notably through its large volume (5.5L, of which 3.2L is available for use) and its horizontal structure, two key features that promote the spread of biomass and allow for better light transmission.

The plastic used – medical polycarbonate – presents a high resistance to autoclaving, is low weight and has perfect transparency favoring photosynthesis and plant development.

The overall design of the bioreactor MATIS® increases the quantities of plants produced while reducing the culture time. When compared with other cropping systems, temporary immersion, vigor, physiological state and homogeneity of the regenerated plant material are greatly improved. At the exit of the bioreactor, the plants acclimatization performance in the MATIS® is much higher than those observed in other cropping systems: improved recovery and greater uniformity of plantlets batches under natural conditions.

The use of MATIS® will enable you to increase your production capacity and plant quality while minimizing the number of handling phases.

A- Plant mass obtained after 2 months in MATIS®

B- Plantlets obtained after 2 months in MATIS®

Industrial laboratory results on somatic embryogenesis of coffee tree

- After 6 weeks in MATIS®, 66% of mature somatic embryos are converted into plantlets

- Ex vitro, the rooting rate of plantlets is 99%

- After transfer to greenhouse, the final plant conversion rate is over 85%

- The resulting plantlets are well developed and show a synchronous development

- The obtained plant material is of very good horticultural quality and meets commercial requirements

TECHNICAL SPECIFICATIONS

| Useful volume for plants | 3,2 L |

| Minimum air flow (required for immersion) | 2 to 5 l/mn |

| Plantlets optimal capacity/MATIS® | 600 – 1000 |

| Autoclaving | Extremely resistant |

| Material | POLYCARBONATE (PC) transparent |

| Dimensions (diameter x height) | Ø290 mm x 180 mm |

| Empty weight | 1,1 kg |